c-Alice

The All-Images-Classification-Engine for semiconductor manufacturers

Convanit provides a complete solution for AI based image classification to enable manufacturing companies to automatically analyze images of any type.

Well suited for semiconductor industry, electronics manufacturing, automotive, plastics, pharmaceutical and food industry

Works for a large variety of industrial cameras, inspection and vision systems including optical and scanning electron microscopes, defect maps and electrical test data.

centralized

One centralized AI-framework for the whole production site

independent

Independent of imaging systems

customizable

optimized algorithms based on use case

Your benefits

one for all

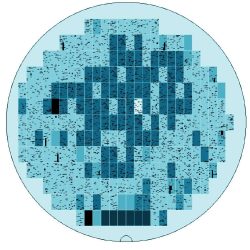

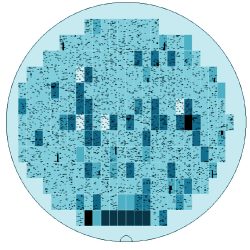

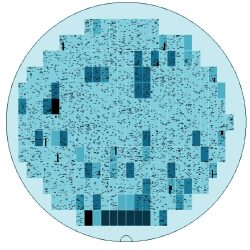

c-Alice can classify all types of images: any type of inspection / microscopy, wafer maps, test maps and others.

fast & accurate

c-Alice generates classification results in seconds. High accuracy is achieved by using fast and optimized algorithms.

complete workflow

c-Alice provides image and recipe management including versioning, monitoring, deployment and meta data integration. Low maintenance effort and reduced manpower ensure efficient classification in production.

easy set-up

c-Alice allows easy recipe set up without further AI knowledge. Users can manage images and context data comfortably in order to train, verify and release recipes.

flexible

c-Alice is based on a modern architecture and can be integrated flexibly in your production environment.

Use Cases

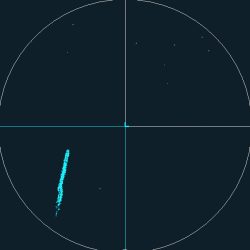

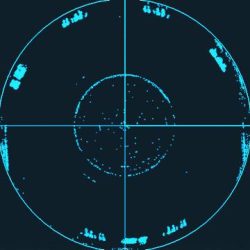

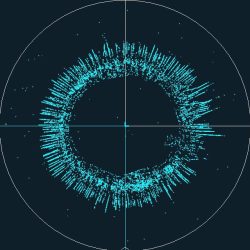

Classification tasks

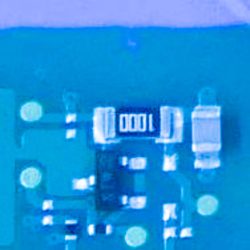

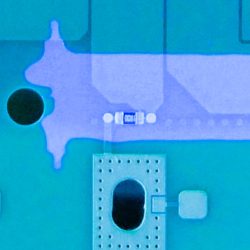

classification of failure types in defect images (scratches, holes, particles, stains, missing structures and more), reduction of pseudo defects, color control

Anomaly detection

find unexpected deviations

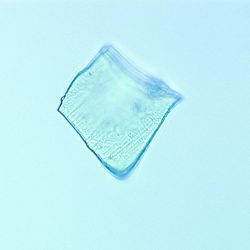

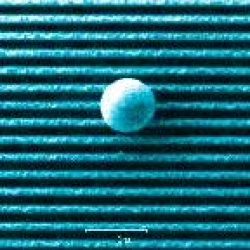

Pattern, structure and surface analysis

pattern recognition of defect and binsort wafer maps, structure analysis of materials and liquids and more

Object detection

counting, position control, completeness check

From classification towards characterization

Beyond just image classification, c-alice can process arbitrary data along with the images to characterize defects and other problems.

Who we are

10+ experts are working on the c-Alice project

convanit GmbH & Co. KG

combination with IT and data science

Founded in

in Germany

Experts with more than

years of industry expertise in production control

Projects in more than

manufacturing sites

Our Networks

Cooperation with several local AI expert groups within university and institutes

Silicon Saxony

VDI/GMM

SEF

Smart System Hub

Silicon Saxony

VDI/GMM

SEF

Smart System Hub

Selection of our clients

Latest publications

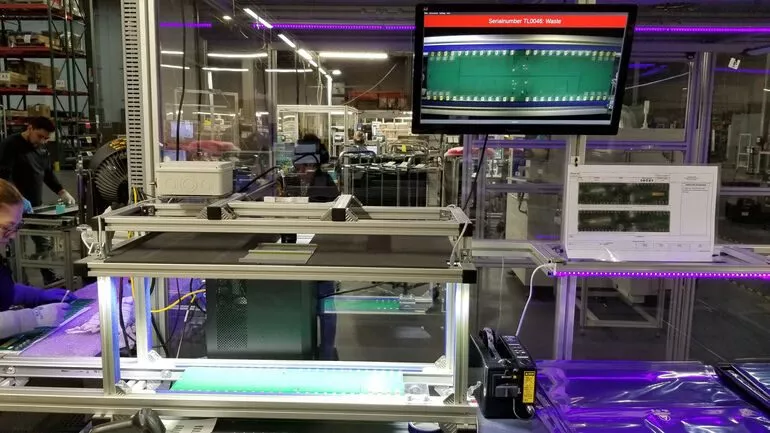

KI zur Qualitätskontrolle von Platinen

24.02.2024

Limtronik geht nächste Schritte in der Automatisierung und in Richtung Künstliche Intelligenz. So optimiert die Elektronikfabrik die Qualitätskontrolle von Platinen mit einem Kamerasystem und automatisierter Bildauswertung. Zur Auswertung der Bilder kommt die Software c-Alice der Firma convanit mit KI-basierten Modellen zum Einsatz. Ziel ist es, den Verarbeitungsprozess abzusichern. Die Anwendung wurde am Standort in Limburg an der Lahn getestet und für die Dependance in Aurora (Colorado/USA) ausgeprägt.

Silicon Saxony - Smart Systems: Vom individuellen KI Anwendungsfall zur zeitnahen bezahlbaren Umsetzung in der Fertigung

Im KMU Bereich gibt es noch viele ‚ungehobene Schätze‘ im Bereich KI, wie zum Beispiel in der Fertigungskontrolle. Fachwissen, KI Methoden und Daten sind zwar vorhanden, jedoch fehlt für eine produktionsreife Lösung häufig noch das richtige Konzept zur pragmatischen Verbindung dieser Komponenten. Der Weg dahin muss nicht schwer sein, wenn man sich auf das Wesentliche konzentriert.

Digitale Welt: KI in der Fertigungskontrolle – Herausforderungen und Strategien

21.03.2023

Für die Bewertung von Zeitreihen-, Bild- und anderen Daten, ist gerade bei Zuordnungs- und Klassifizierungsaufgaben und der Erkennung von Mustern und Anomalien der Nutzen von KI Methoden hoch. Die dafür notwendige Rechenleistung ist heute ‚bezahlbar‘ und erprobte Mathematik sowie mächtige Open-Source Softwarebibliotheken stehen zur Verfügung. Dieser Artikel beschreibt Herausforderungen bei der Einführung von KI Methoden in der Fertigungskontrolle und die daraus abzuleitenden Strategien.

We are supported by